RENEWABLE RAW MATERIALS & MATERIALS

The possibilities and alternatives to familiar packaging raw materials: Most of today's product packaging is made primarily from conventional materials such as plastic or cardboard. And for good reason: they have institutionalised value chains that have been optimised over the years and therefore simply work very well. However, the finite nature of resources is promoting not only the classics but also alternative packaging materials that are increasingly shaping consumer attitudes. Renewable raw materials and materials are becoming increasingly popular when it comes to the final switch away from conventional plastics.

For the vast majority of products, the switch from plastic packaging to cardboard packaging should be considered first and foremost. This is because paper is resource-saving and efficient and, thanks to its recyclability, a wonderfully sustainable material that is ideal for the production of packaging. However, other renewable material alternatives, such as grass paper or paper pulp, are also increasingly entering the market and are becoming more and more economically attractive.

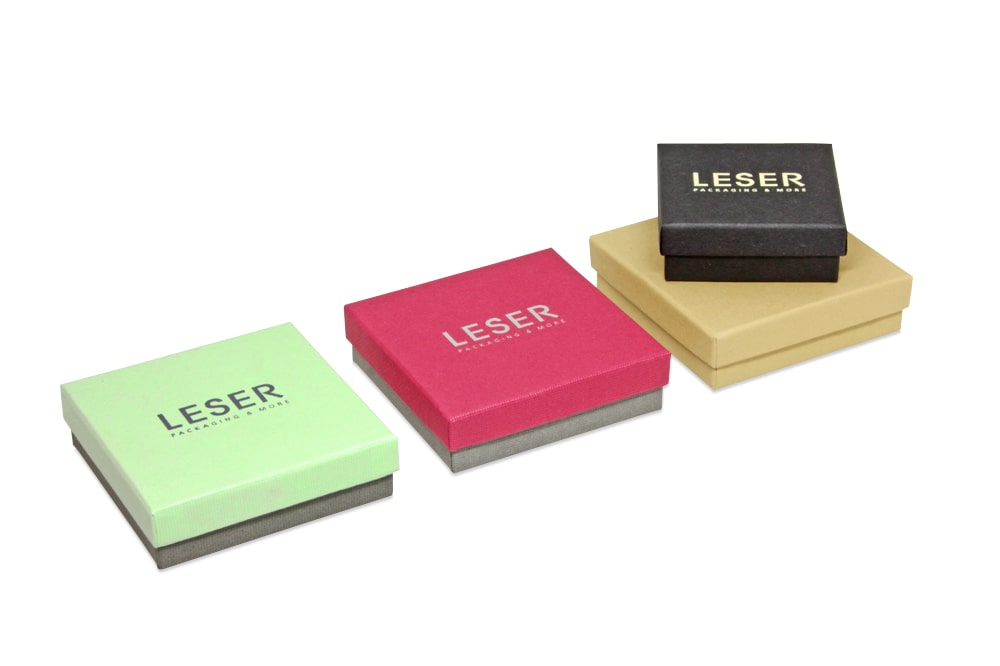

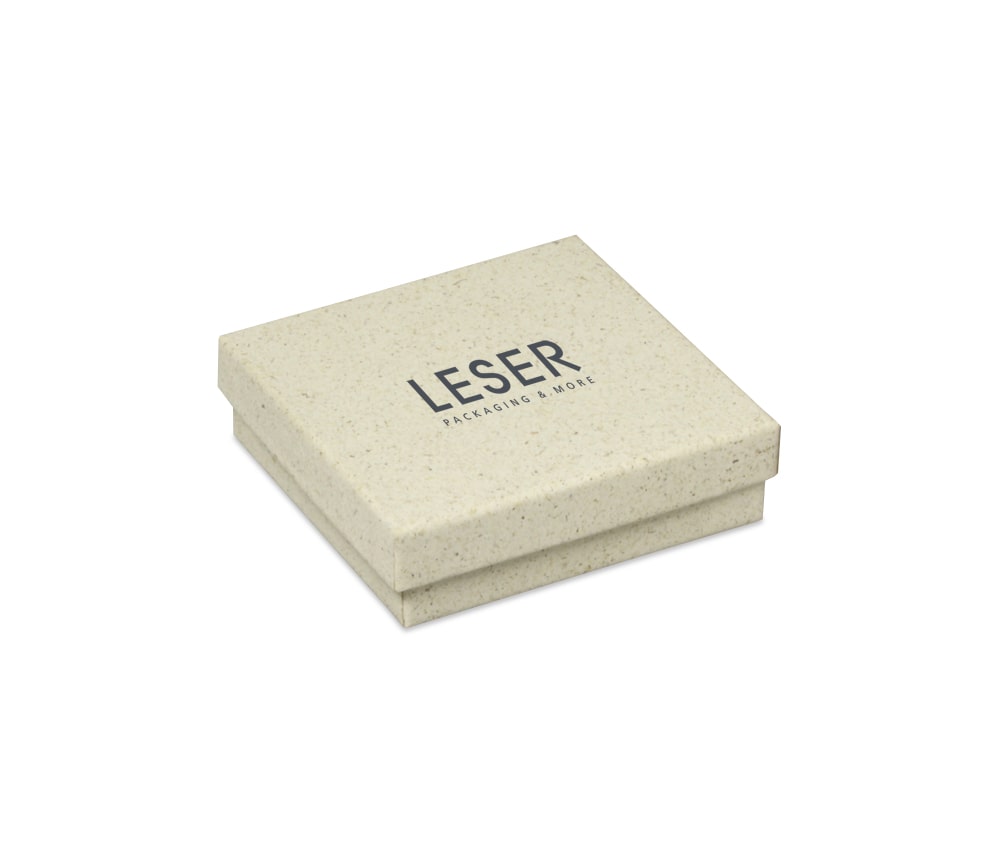

Sustainable cardboard boxes

Approximately half of the paper consumed in Germany comes from recycled fibres recovered from waste paper. In our cardboard box production, for example, we work with cardboard that consists of up to 100% secondary fibres (recycled paper).

- Cardboard: The solid cardboard used as the body of the packaging consists of up to 100% recycled fibres and is also recyclable. Corrugated cardboard can also be used as an alternative. Both materials can also be processed in FSC®-certified versions.

- Paper: The paper used as the outer layer of the packaging is available in FSC®-certified, REACH-compliant, 100% recyclable and biodegradable versions. Alternatives such as grass paper and stone paper are also used.

- Glue: The glue used to attach the components is a biodegradable natural product made from water and gluten.

- Inks: The majority of the printing inks used to finish our packaging are water-based.

- Inserts: As an alternative to classic thermoformed inserts, a range of sustainable insert materials are also available.

- FSC® certification: Since our company was certified, we have been able to produce customised cardboard boxes according to your specifications, including in FSC® materials. You can find out more about FSC® and other labels here: Labels.

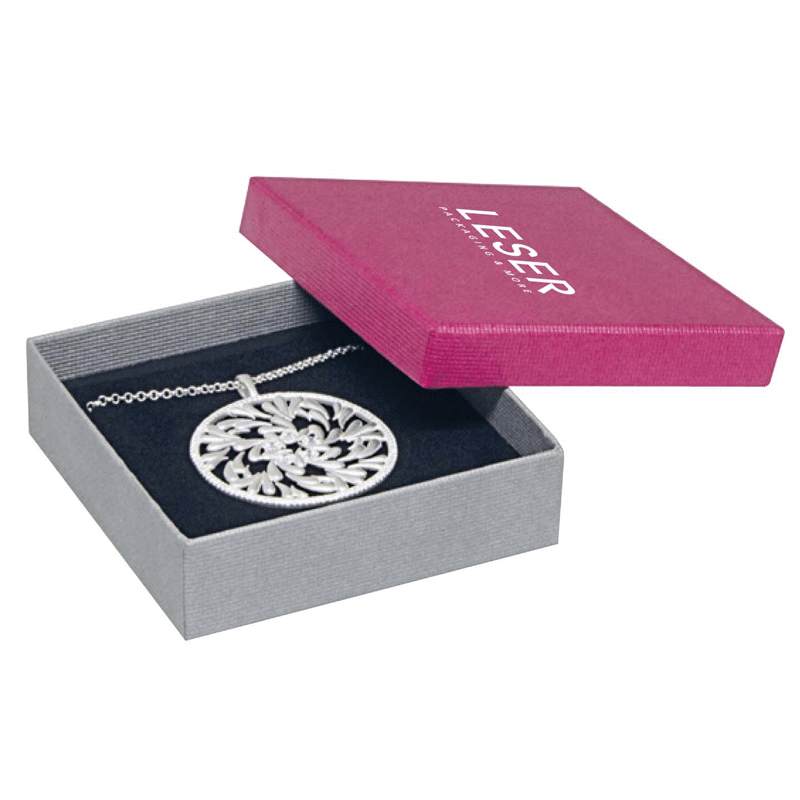

Packaging with the FSC® label

In terms of materials and raw materials, it can therefore already be said that cardboard packaging is a very resource-saving and environmentally friendly packaging solution. Incidentally, around 90% of the wood used by European industry for further processing comes from the European Union itself. And around 60% of this comes from sustainably managed forests, according to a study by the folding carton industry association Pro Carton. The use of various labels also gives end consumers a certain amount of guidance about the origin of the materials used. In our case, for example, this is the FSC® label, which our customers requested. Consumers and customers can be sure that the wood chain for the cardboard and paper we use is fully monitored. In addition, consumers can use the licence number to carry out their own certificate check at any time.

Since obtaining FSC® certification (Licence number: FSC® C144083), we have been able to produce cardboard boxes according to your specifications in accordance with the FSC® standard – just ask us about the options available!

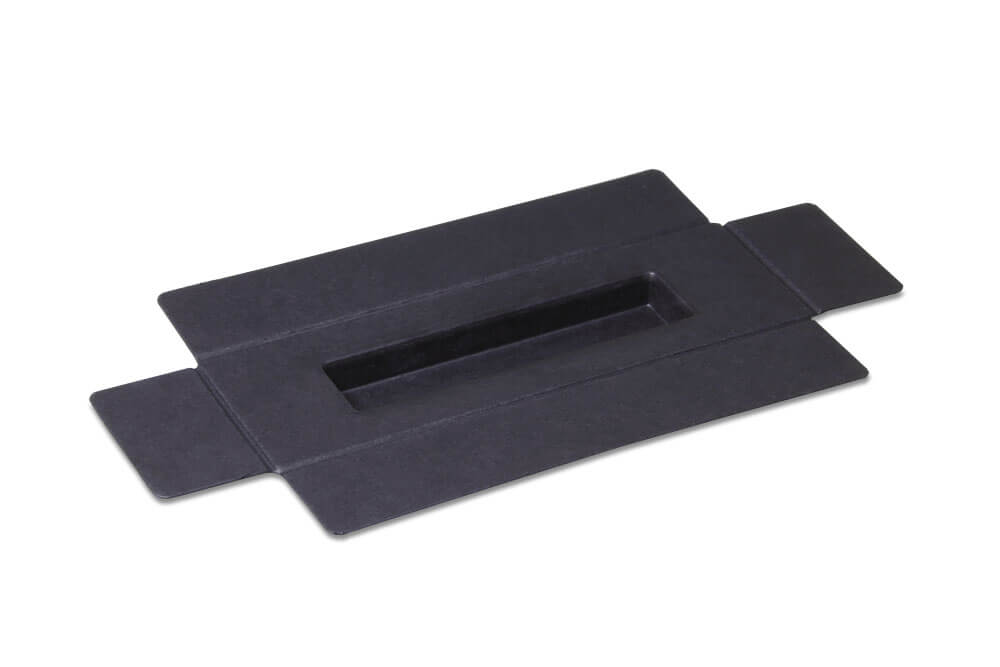

Cardboard inserts

Cardboard inserts are an absolutely sustainable alternative to conventional plastic thermoformed inserts and ensure that products are held securely in place in their packaging. These are developed specifically for each product in our production facility in southern Germany. It makes no difference whether the inserts are intended to hold one product or several in the packaging. The recesses for your products are machine-punched and can be flexibly designed. Cardboard inserts can be made from both corrugated cardboard and solid cardboard. They are basically suitable for all packaging and slip-lid boxes. However, cardboard inserts reach their limits somewhat faster than thermoformed inserts: When used in round packaging or boxes in special shapes, their feasibility must first be checked on a case-by-case basis – for rectangular and square boxes, however, cardboard inserts are the perfect, sustainable packaging insert.

Packaging inserts made from paper pulp

The result of this production process is sustainable packaging inserts that resemble egg cartons in terms of function, manufacture and appearance. In addition to this product, however, high-quality products with very smooth surfaces are also possible. Thanks to their outstanding properties, paper pulp inserts are particularly suitable for product packaging and articles in the cosmetics industry. The advantages:

- Based on renewable raw materials

- Can be printed or varnished at a later stage

- Colours: white, brown & black

- Also available in a water-repellent version

- Immediately recognisable to consumers as environmentally friendly

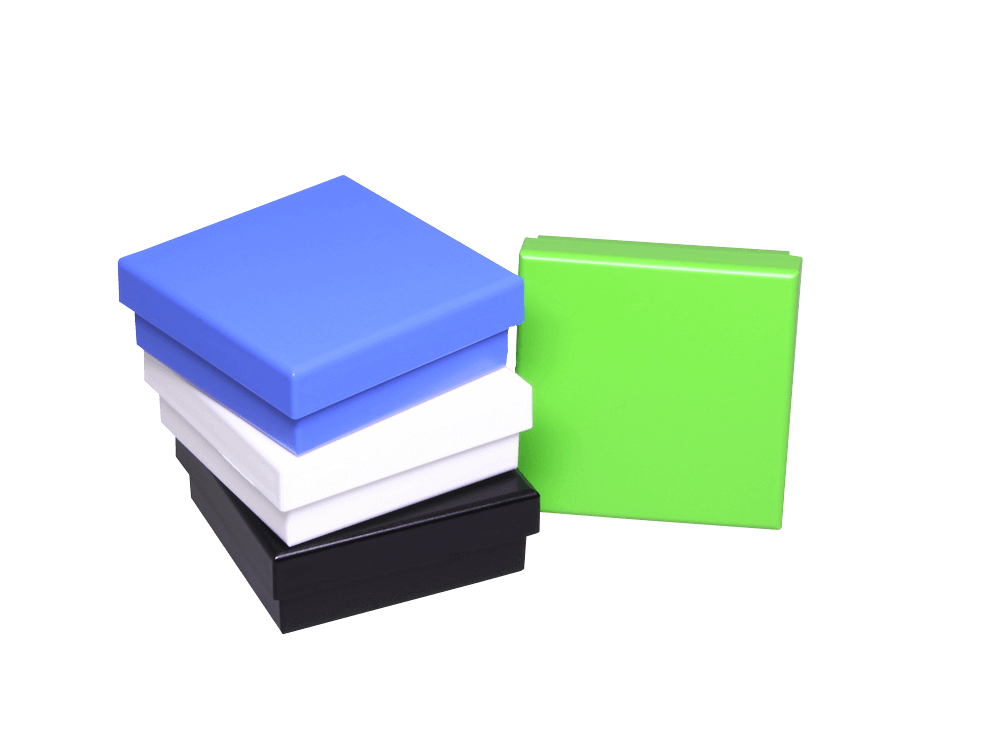

PLA packaging

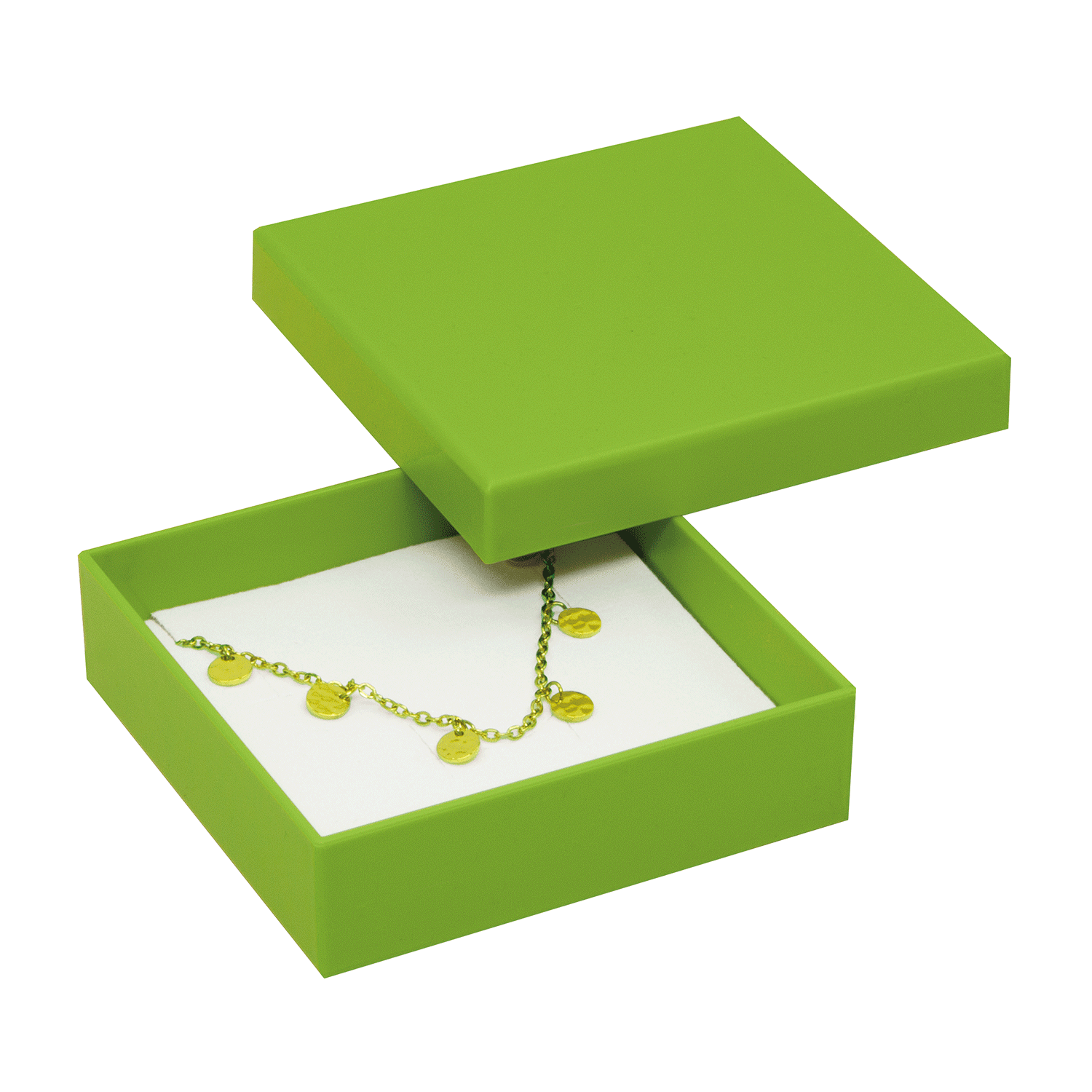

The bio-based plastic PLA, for example, is made from natural raw materials and, more precisely, is obtained through a multi-stage synthesis from sugar. Due to its compostability, PLA packaging is in many cases a far more ecological solution than regular plastic packaging.

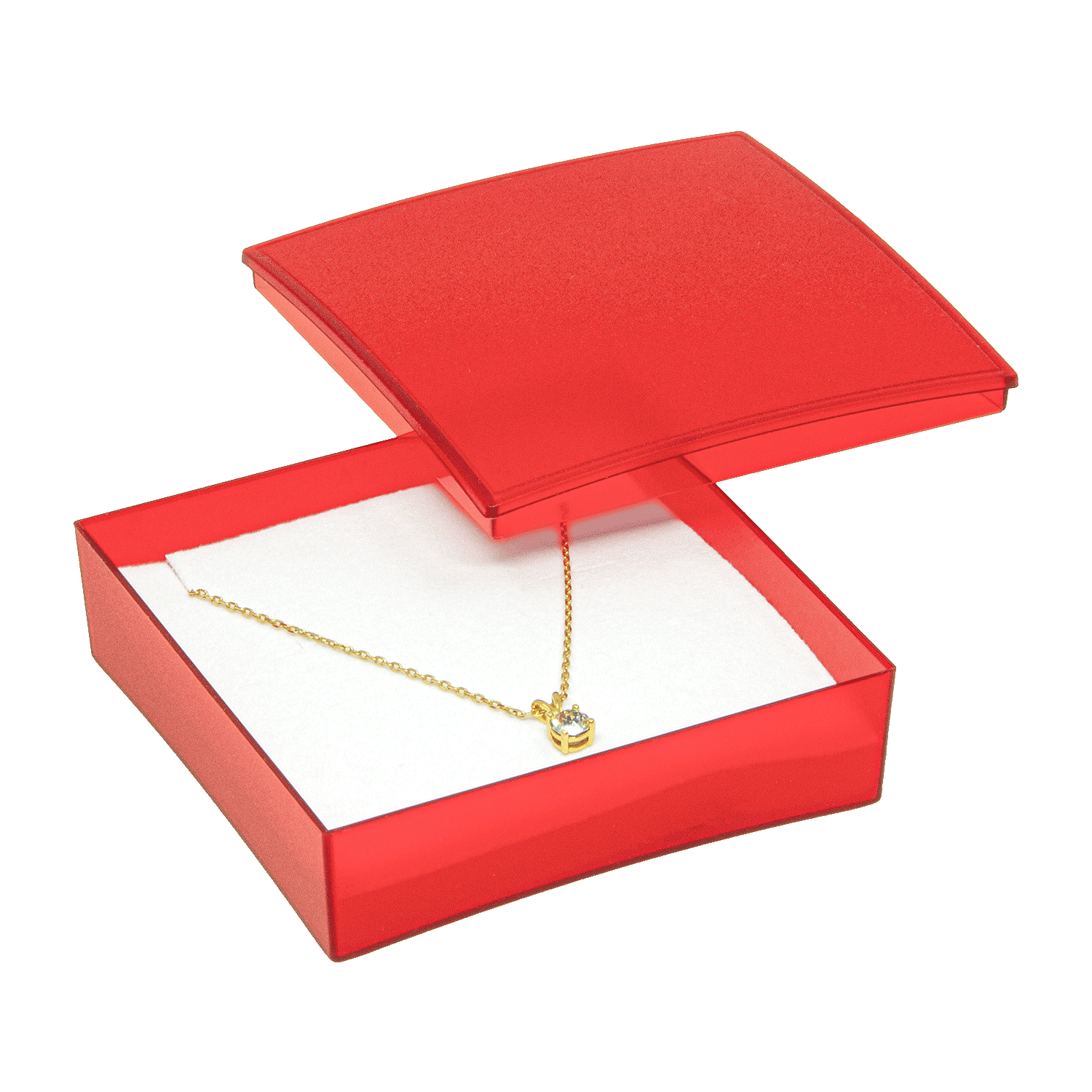

The picture shows an example of our bio-plastic boxes from the 1560 EARTH series – the world's first compostable jewellery packaging.

Deep-drawing inserts made of PLA

In addition to cases, it is now also possible to produce thermoformed inserts from PLA. If you are unable to switch to alternatives made from cardboard or natural materials due to specific requirements, PLA inserts are a solid option for the time being. The only difference is the environmentally friendly raw material – to the naked eye, the sustainable thermoformed inserts are indistinguishable from conventional ones. However, there is one small drawback to using bio-based thermoformed inserts: due to their low material thickness, they tend to deform at temperatures above around 60° Celsius and are therefore not suitable for every product!

Coating material made from grass paper

Grass paper is currently an alternative for anyone who wants to avoid using industrial materials in the design of their cardboard boxes and packaging. Thanks to the flexibility of the material, it can be used to finish packaging in a wide variety of sizes. This makes it a thoroughly green packaging option: with grass paper packaging, you are making a statement to your consumers and also using renewable resources that offer a number of advantages:

- Grass is a renewable & natural raw material

- Harvested three times a year

- Available in large quantities

- Highly flexible in processing

- Not destroyed by harvesting

- Available in different grammages & mixing ratios

- Provides habitat for bees and insects

- Can be finished in many different ways

Cotton as packaging inserts

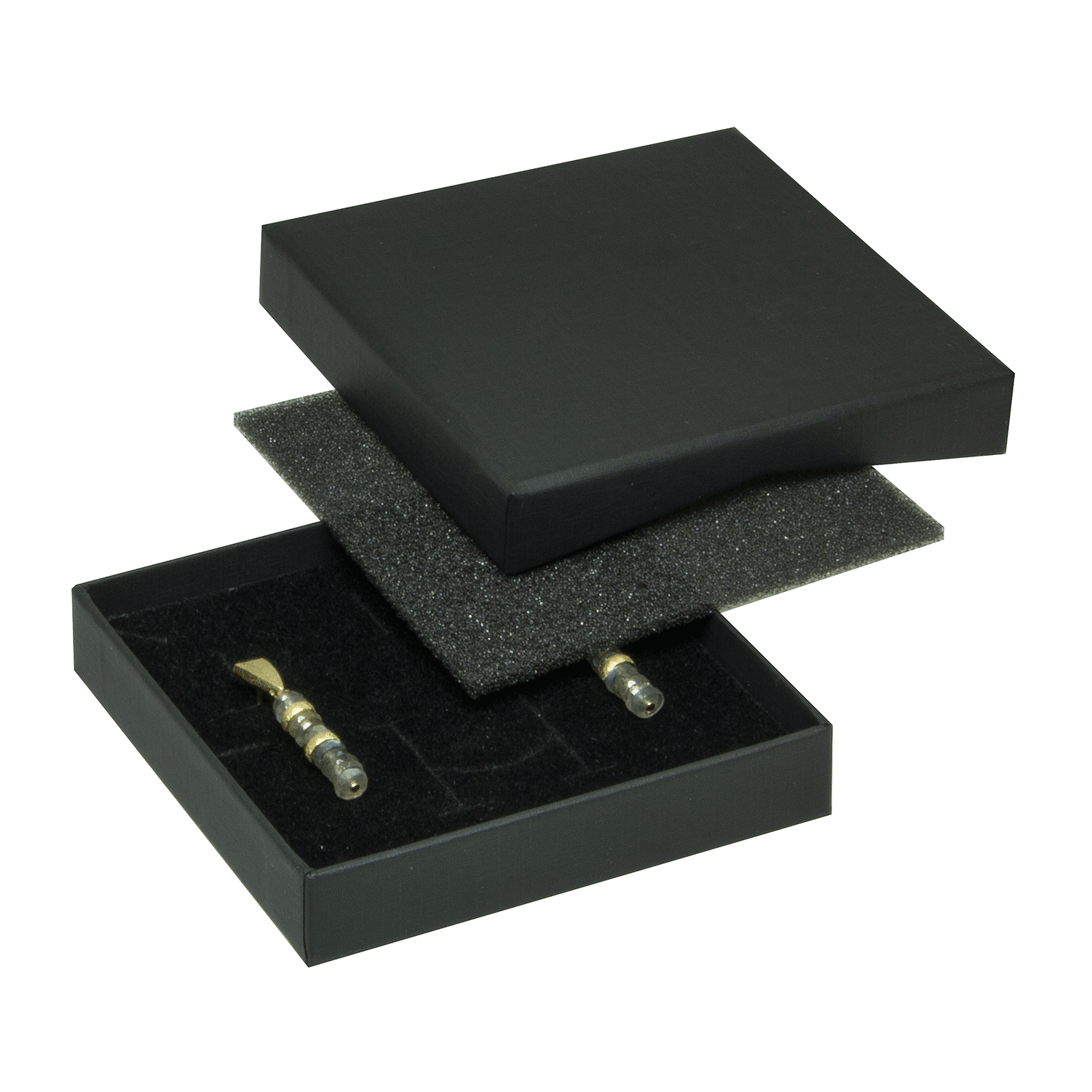

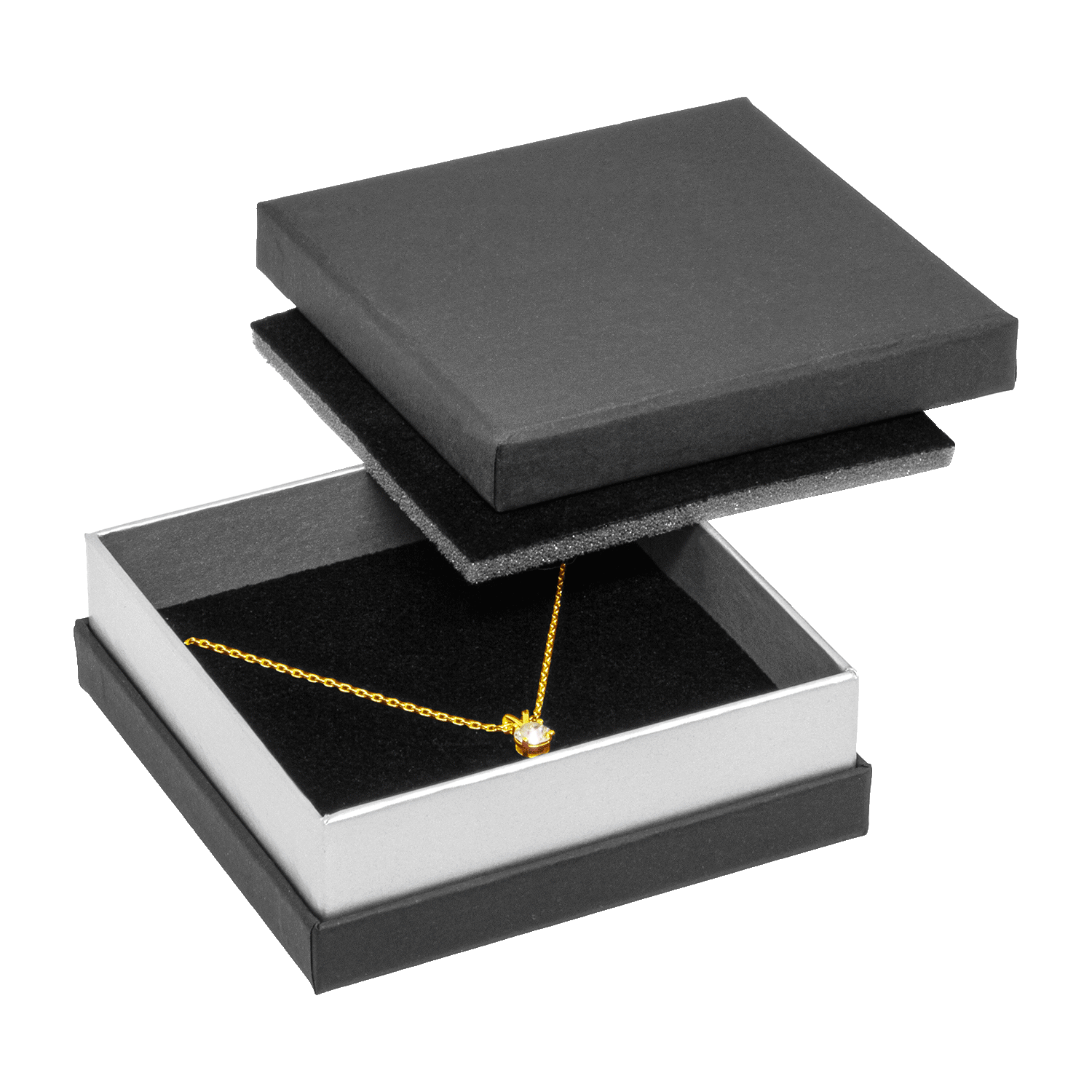

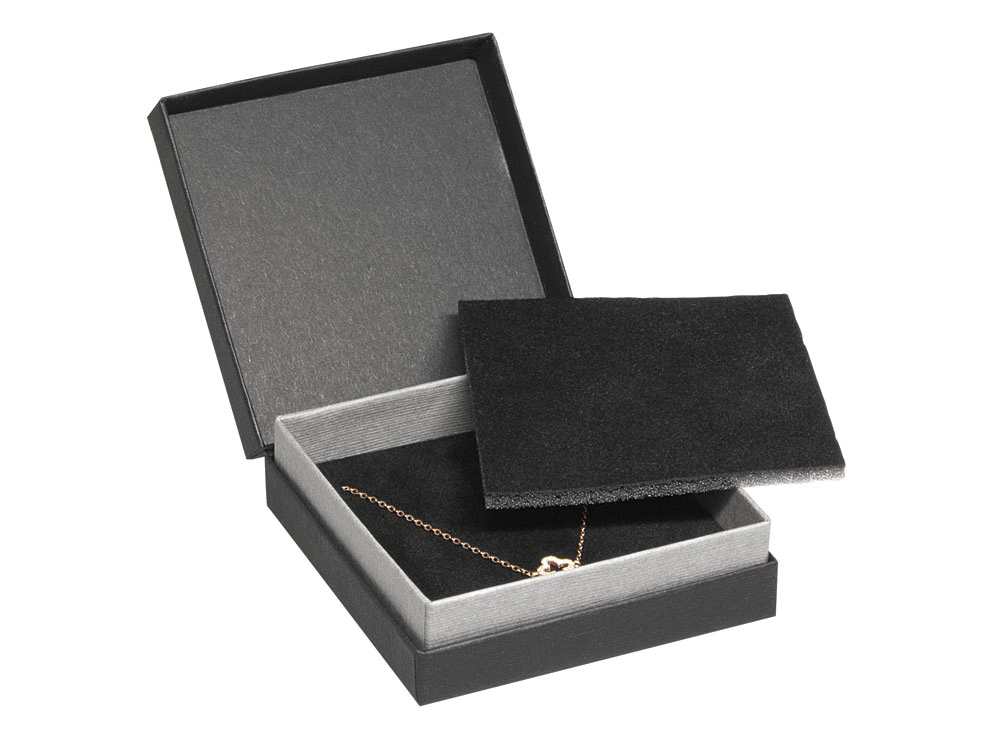

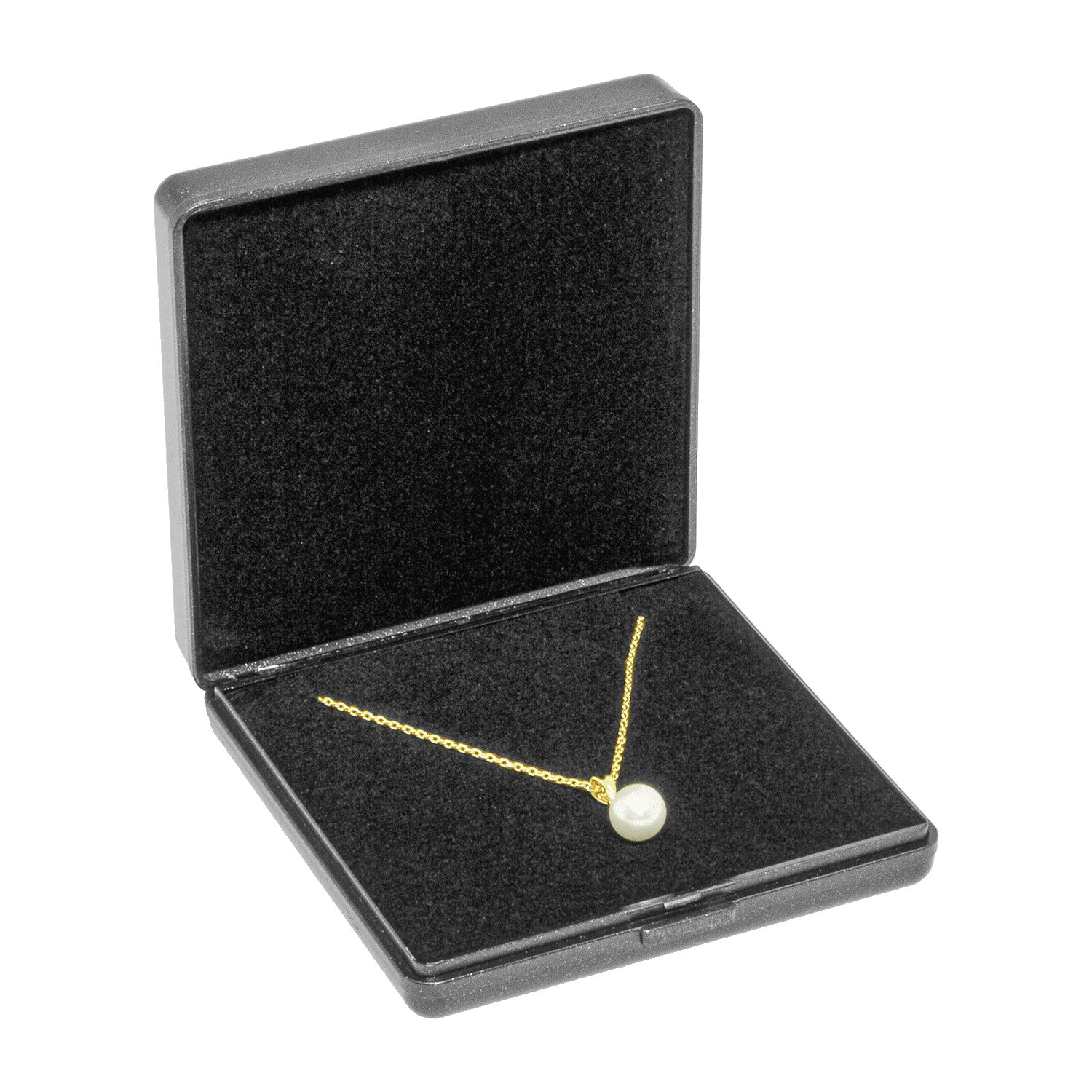

Cotton in the form of jewellery cotton wool is also ideal as an alternative filling material for packaging. It is frequently used in the jewellery sector to replace traditional foam inserts.

This is because cotton protects jewellery, prevents unwanted tarnishing and can be used in a variety of ways for different pieces of jewellery. What's more, the material consists exclusively of renewable raw materials and is easy to process thanks to its properties.

Packaging made from other alternative materials

Bamboo packaging

Packaging made from milk proteins

Containers made from algae

Packaging made from mushroom mycelium

As a natural alternative to Styrofoam moulds, the American company Ecovative manufactures packaging from biological waste and fungi, which grow into shape on their own. The natural waste serves as food for the fungi and is completely metabolised. After about five days, the mushroom mycelium has grown into shape and is then exposed to intense heat to stop growth. The result is a mushroom mould that is ideal for packaging fragile products.

Limitations of alternative, renewable raw materials

When it comes to packaging production, however, it should be noted that many of the modern alternative materials mentioned here are simply not market-ready for large-scale packaging production. The reasons for this are both economic and technical. Without a comprehensive infrastructure, the production of packaging using modern alternatives is not suitable for mass production. 100,000 pieces of packaging, each of which takes five days to form, not only require a lot of time, but also a lot of space. When considering the materials holistically, it is also important to note that the amounts of energy and water used are often significantly higher than for traditional packaging materials.