HOT FOIL STAMPING FOR STRONG BRAND IMAGES

Making a brand tangible

Hot foil stamping not only gives your packaging a premium look, it also feels that way too. Glossy or matt metallic effects make your brand visible and tangible.

Whether in gold, silver or with coloured effects, embossing creates targeted highlights and effectively accentuates logos, lettering or design elements.

Depending on the technique used, a noticeable difference in height is created, giving your packaging depth and structure. This makes your quality message not only visible, but also tangible.

The embossing is particularly effective on dark backgrounds. The film provides reliable coverage and is abrasion-resistant, even with frequent use.

Hot, precise, effective.

The path to embossing.

During embossing, heat, pressure and a coloured foil come together. The process then proceeds as follows:

First, an embossing die is created – usually with your logo or a design element. This die is then heated and pressed onto the packaging with a lot of pressure. In between is a thin coloured foil, for example in gold, silver or another colour.

The heat causes the ink to separate from the film and adhere precisely to the desired areas of the surface. What remains is a flat, shiny embossing – clean, high-quality and very durable.

This gives your packaging the finishing touch. Whether classic, subtle or particularly noticeable: with us, you can choose between three embossing processes.

Your options at a glance.

Colours, technology, application.

Possible colours

There are virtually no limits to your creativity when selecting embossing colours. You can choose from a wide range of glossy or matt foils – tailored to your brand identity or the desired look.

If you prefer a more subtle look, opt for transparent films or do away with colour altogether. This variant is known as blind embossing and impresses with its elegant, understated effect.

Multi-coloured embossing

Multi-coloured embossing is also possible – up to four colours per motif. This is done by machine with high precision. This means that even complex designs can be realised without losing clarity or impact.

Colour gradients or striking contrasts add targeted highlights and make your design even more expressive.

Advantages at a glance

Embossing not only gives your packaging an exclusive look, but also creates a special feel – and that's exactly what sticks in the mind. The combination of first-class finishing and tangible depth creates a high-quality, durable and professional impression.

Thanks to the wide range of colours and techniques available, a variety of looks can be achieved – from classic to eye-catching. Embossing is particularly effective on logos, slogans or as design elements on packaging or carrier bags.

possible applications

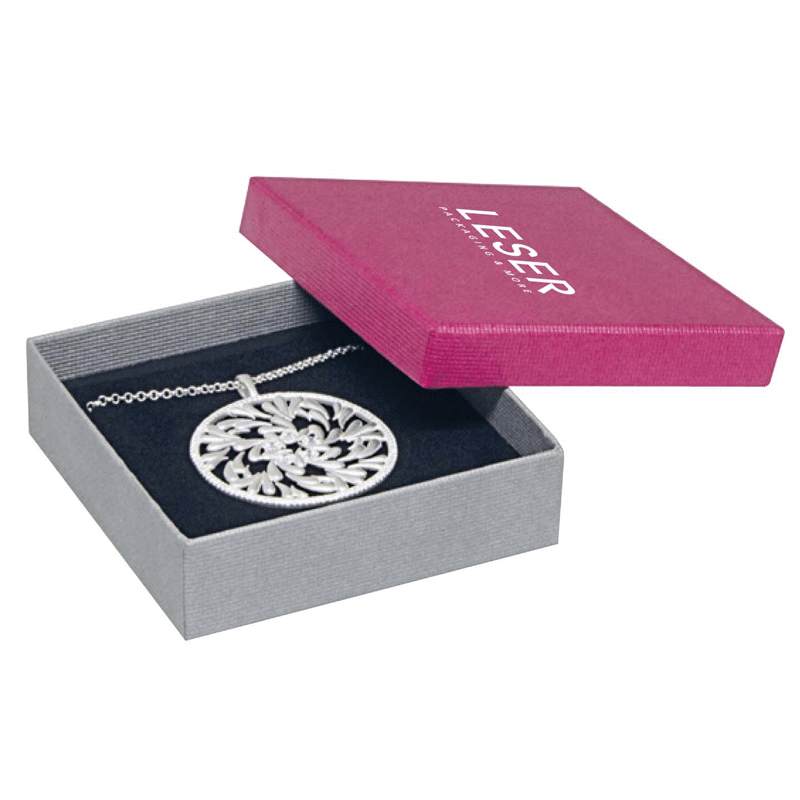

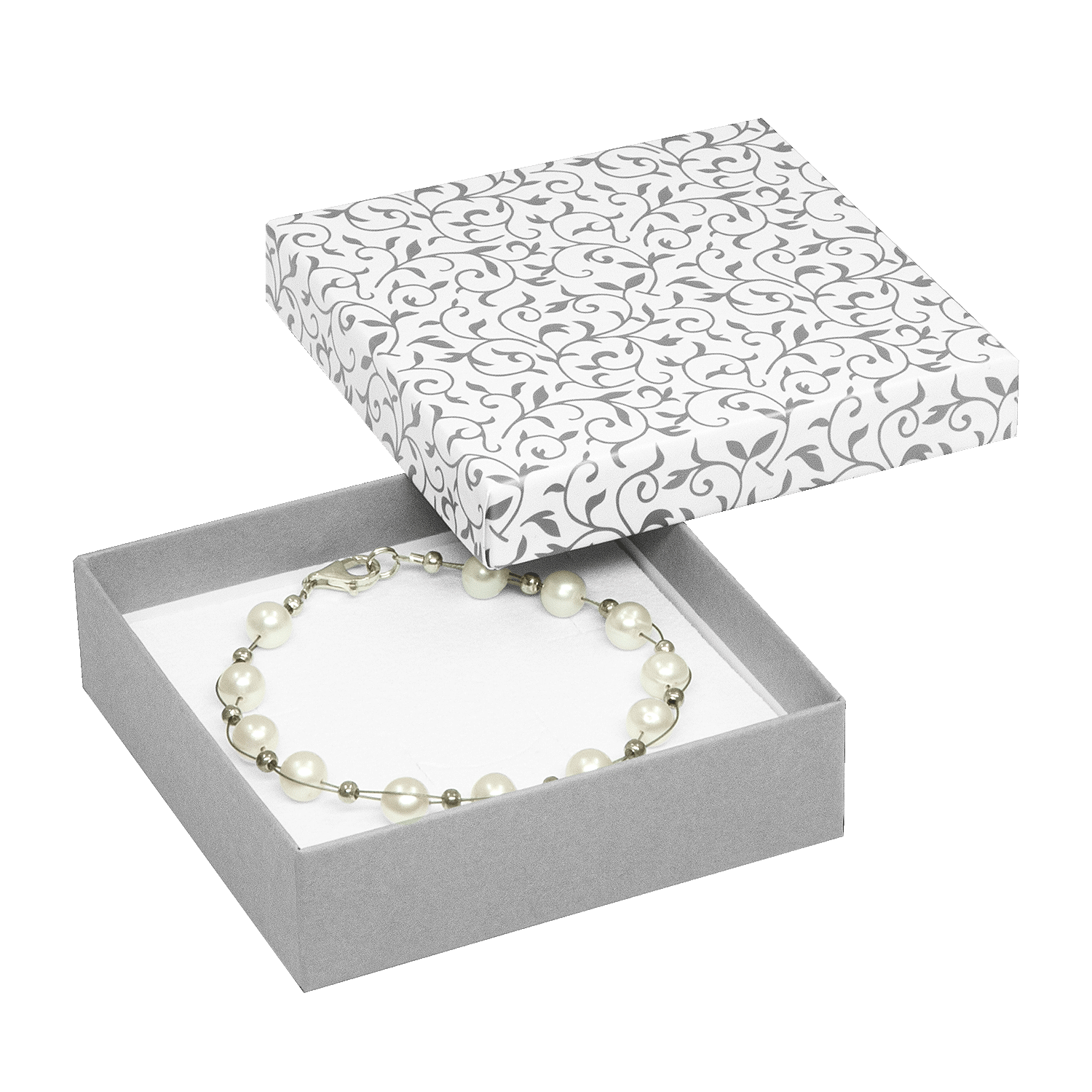

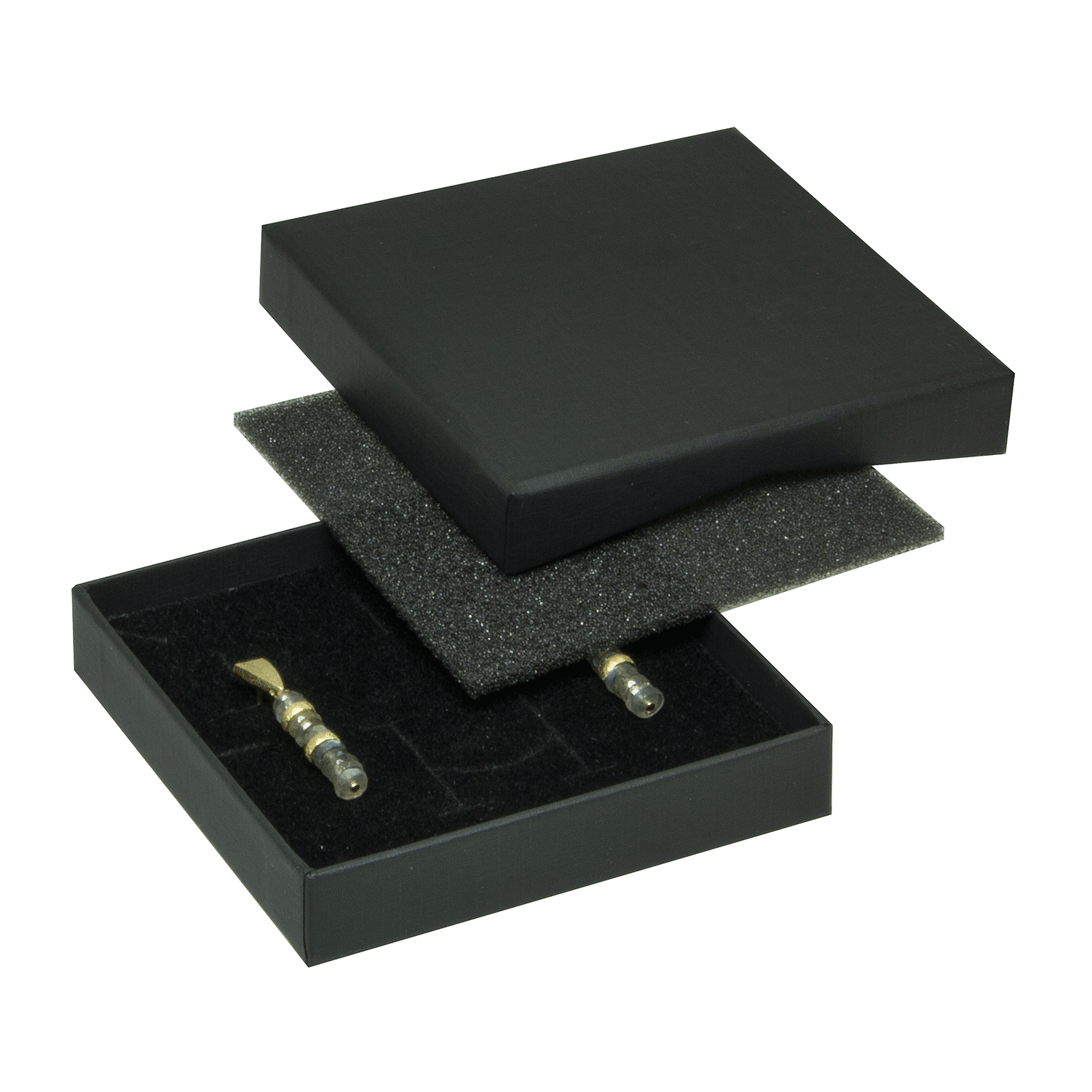

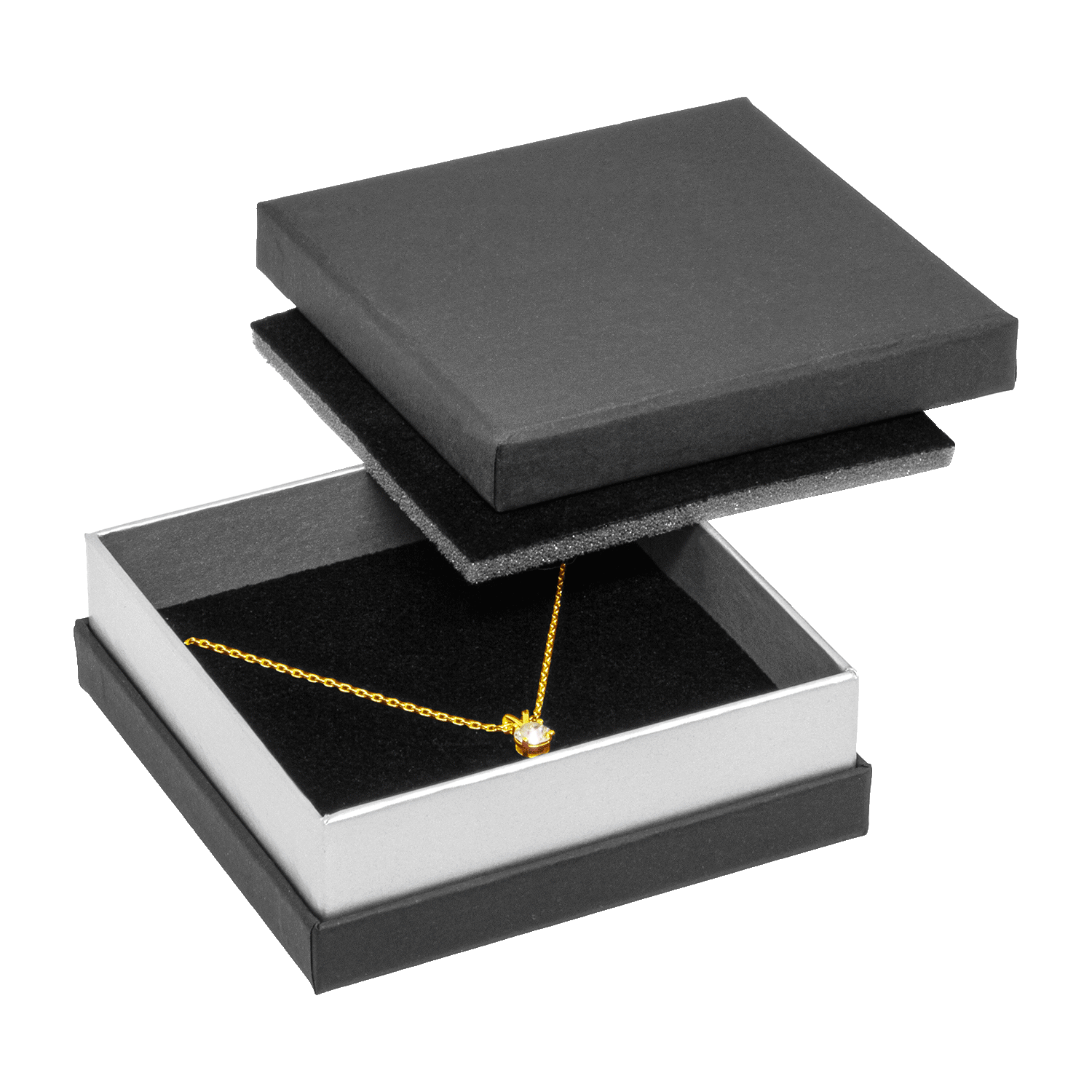

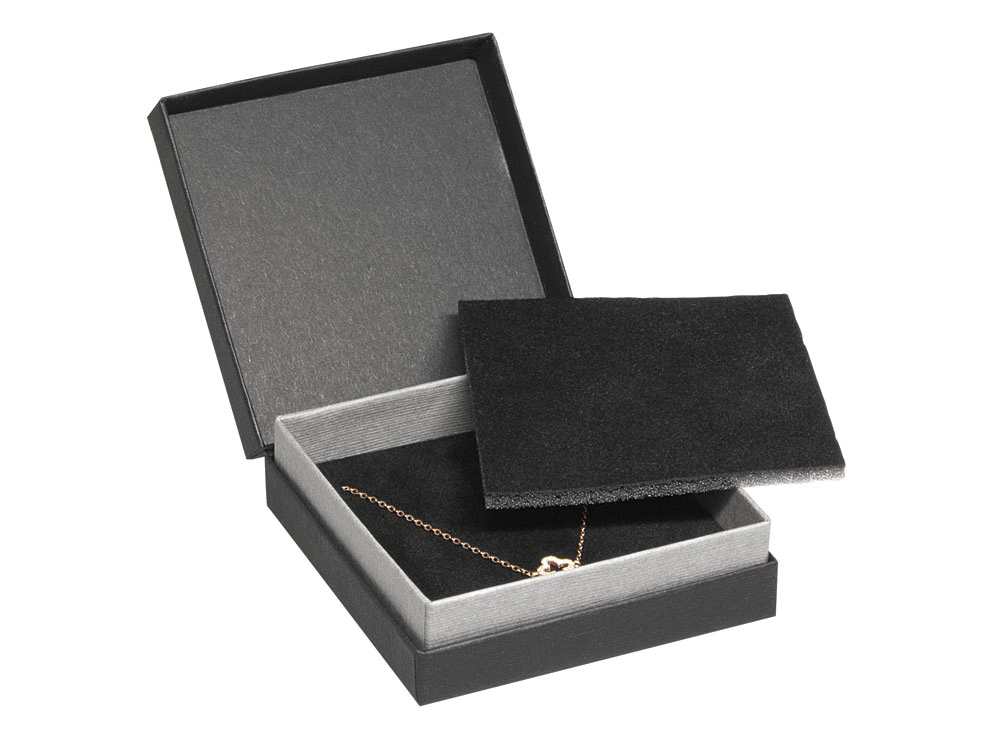

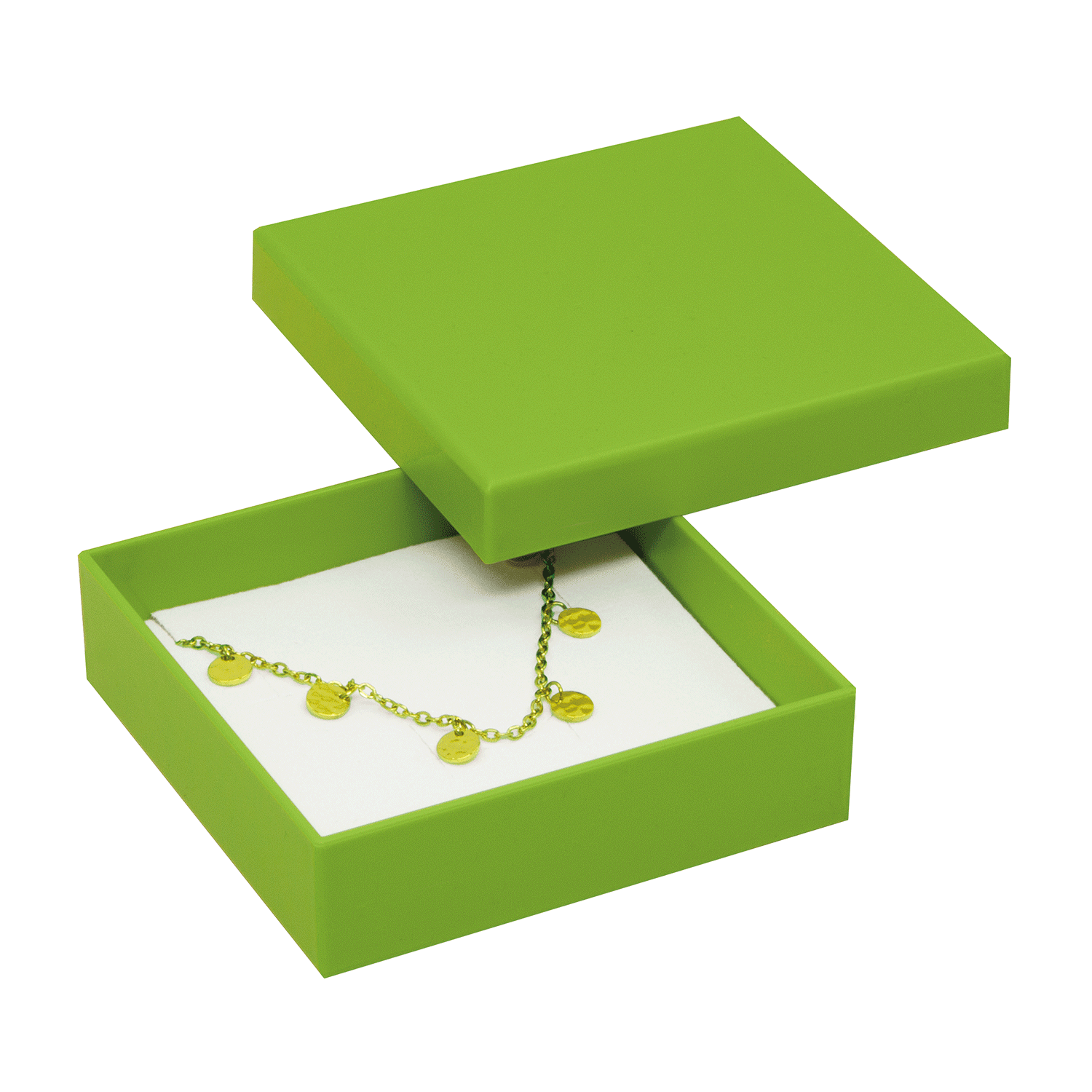

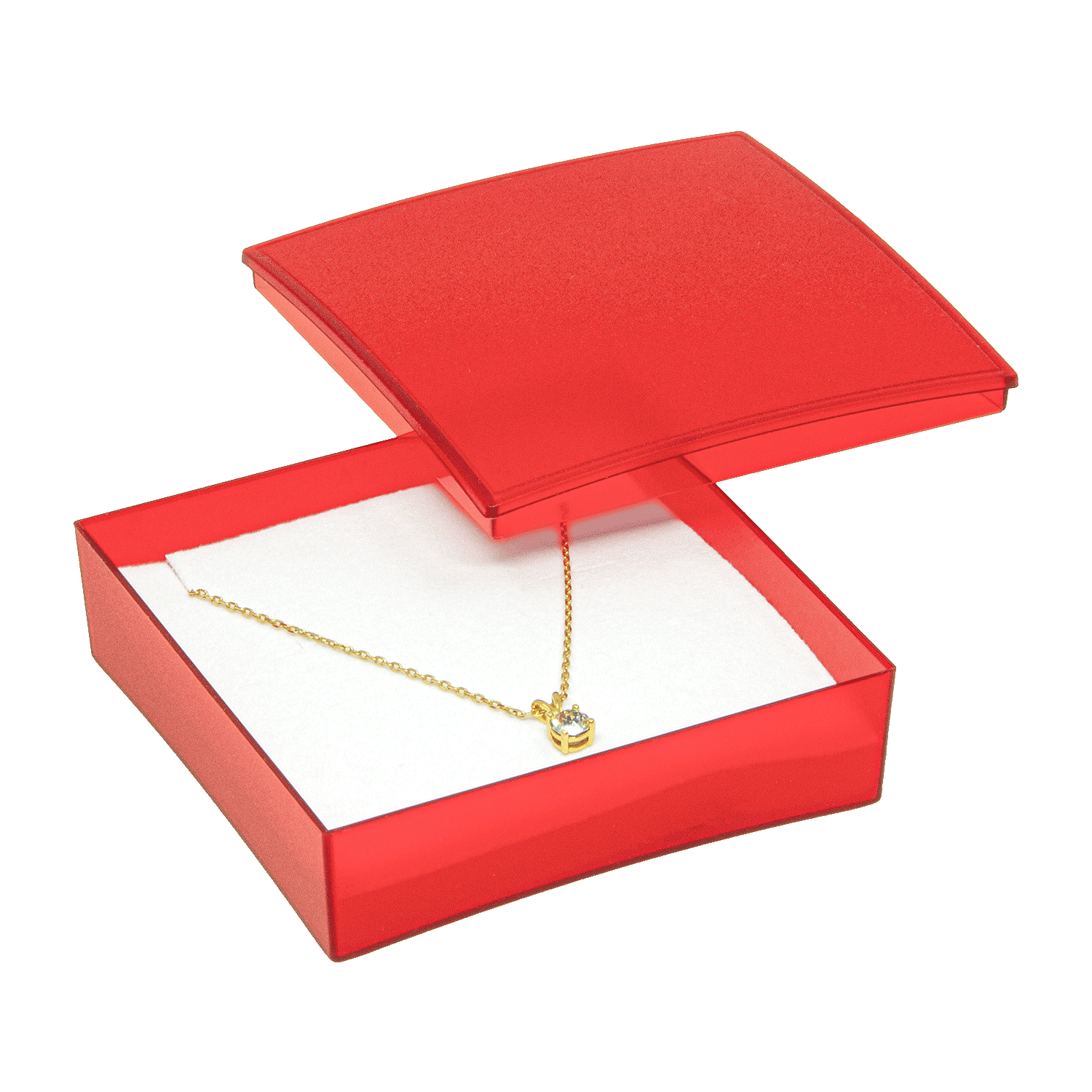

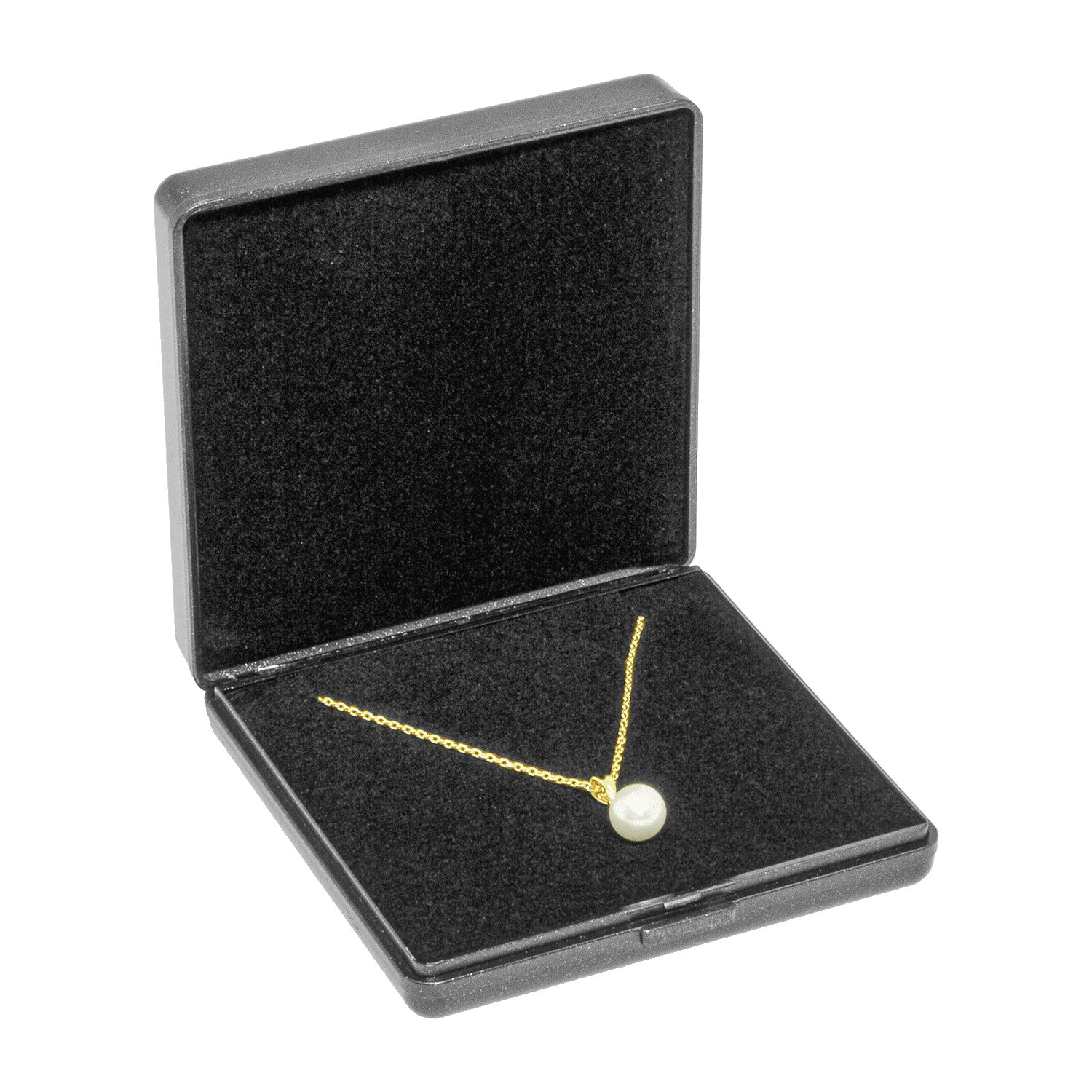

Embossing can be used in many areas and ensures a high-quality appearance everywhere. It is particularly popular on or inside slip lid packaging – for example, on the lid or the inlay.

They also make an effective impression on plastic boxes and carrier bags. In the jewellery industry, embossing is often used on the lid cushions of cases, where it makes a subtle but impressive brand statement.

Customised embossing in 3 steps

Send print data

To ensure that your embossing is perfect, we need your logo, slogan or desired motif in a printable format. Vectorised files such as .ai, .eps or .pdf with at least 300 dpi are ideal. Formats such as .psd, .indd or .jpg are also possible – please ensure that all images are embedded.

Design review & stamp production

Our graphic designer takes care of the finishing touches: we check your data, place the motif in the desired position and create a proof for approval. Once you have approved the proof, we manufacture an embossing stamp from aluminium or brass – in multiple sizes if required, e.g. for different types of jewellery packaging.

Embossing your product

Once everything is right, production begins. Your packaging is embossed either fully automatically or by hand, depending on the material and print run. We optimally coordinate all parameters such as pressure, temperature and holding time to ensure that the result is exactly as you imagine it.

Need help?

We're happy to assist.

Whether by phone, email or contact form – simply get in touch with us. We will respond quickly and personally and will be happy to help you.

Packaging consulting

Phone: +49 (0) 7821 / 5803-39

E-mail: contact@leser.de