OUR CONTRIBUTION TO SUSTAINABILITY

The topic of sustainability evokes associations such as adherence to principles, consideration for future generations and the economical use of natural resources. These are areas in which we have a proven track record throughout our long company history. The LESER company now has a wide range of commitments relating to our environment and sustainable products.

FSC® CERTIFICATION AND PRODUCTS

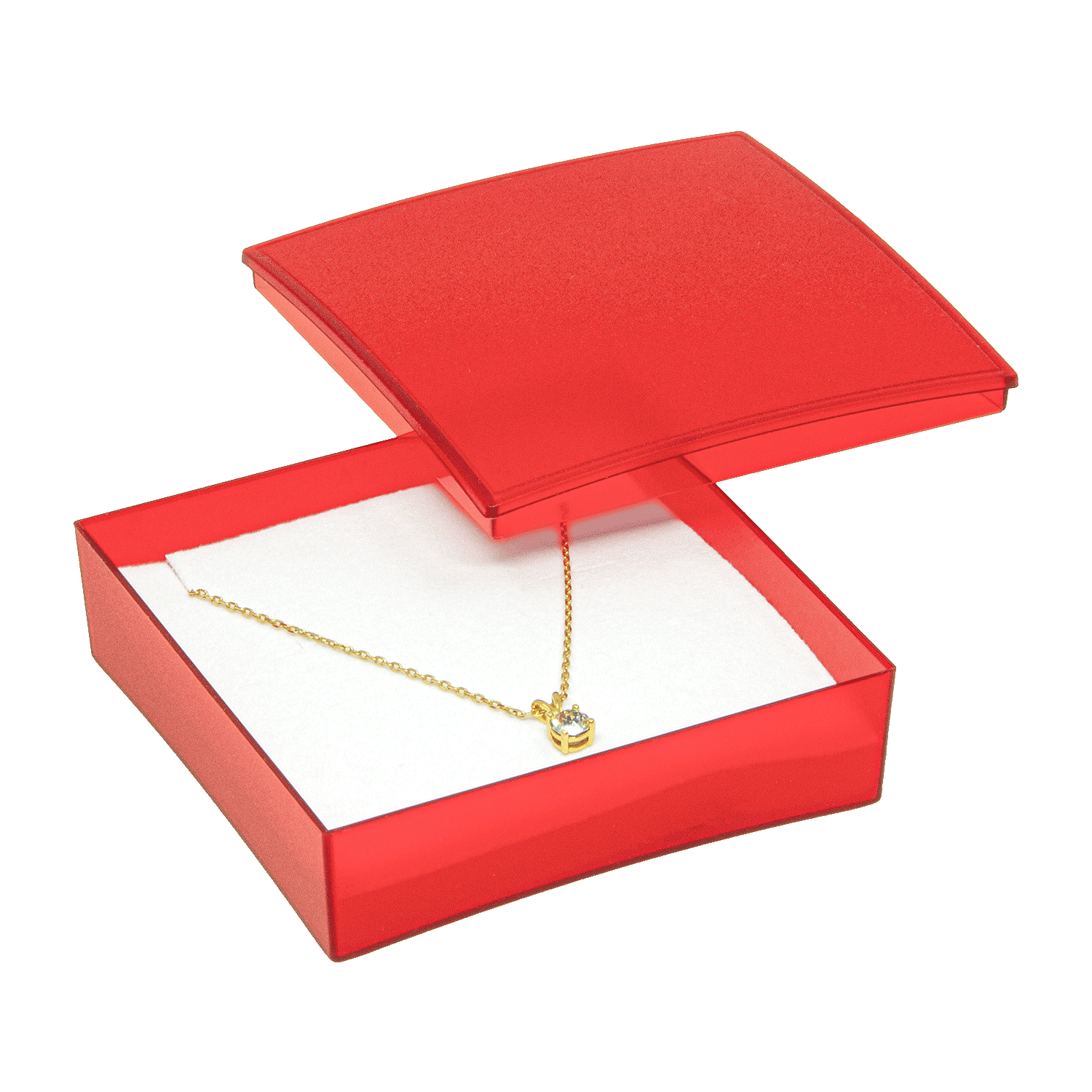

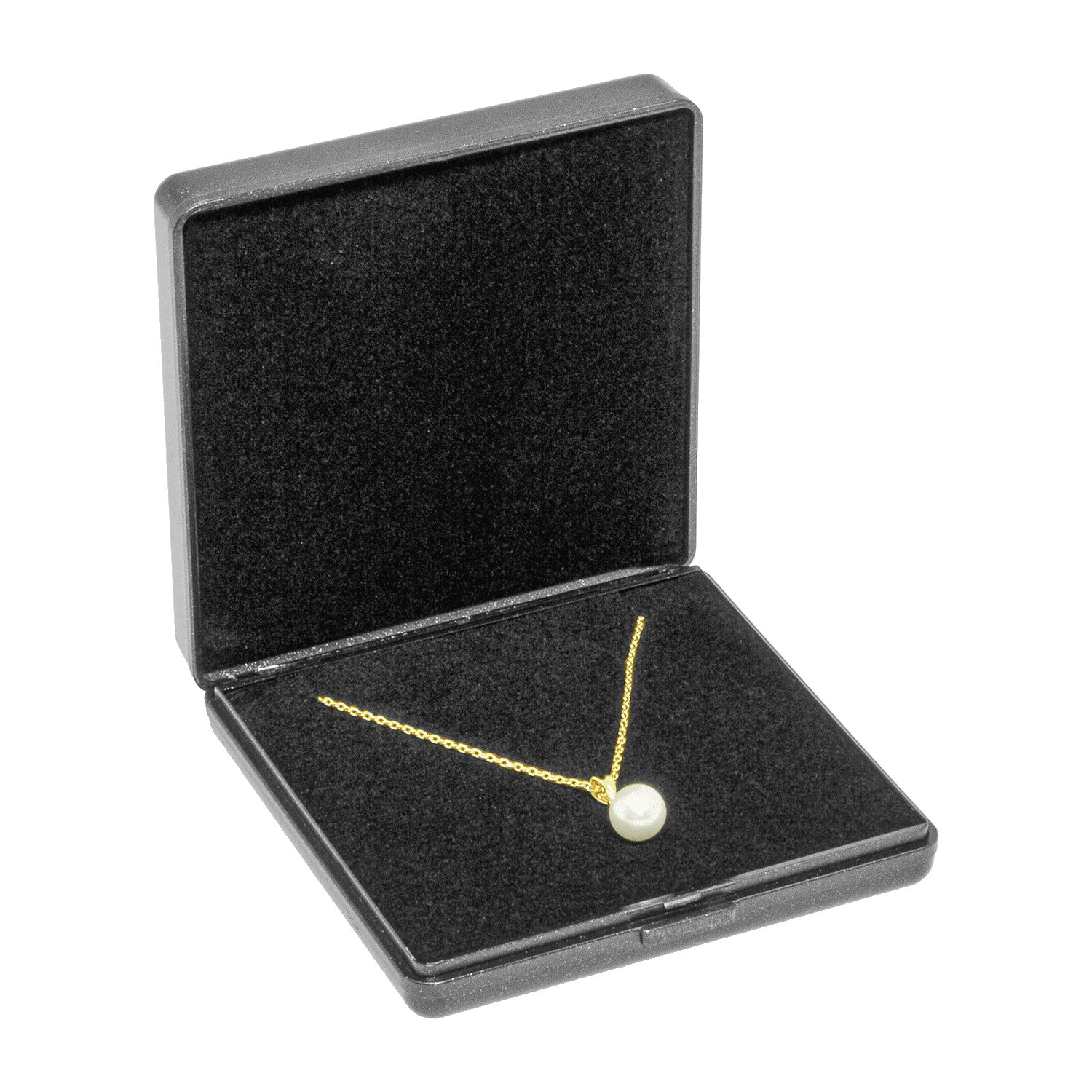

Sustainability – for LESER, this is much more than just a slogan. That is why, in October 2018, our company obtained FSC® certification, in addition to a range of other commitments. Following DIN EN ISO 9001 (quality management system) certification, this certification completes the LESER profile and thus manifests our values. Since then, our portfolio has included products with the FSC® label, whose wood-based materials come from sustainable forestry.

BUT WHAT EXACTLY DOES FSC® STAND FOR?

The Forest Stewardship Council® was founded in 1993 following the Rio de Janeiro Earth Summit. As a non-profit organisation, it promotes environmentally friendly, socially responsible and economically viable use of the world's forests. The FSC® also sees itself as a platform for understanding between the various stakeholders. In this way, socially and ecologically consistent standards are developed that must be adhered to in areas such as forest management. The FSC® is gaining more and more supporters in its mission to combat the ongoing exploitation and destruction of forests. The FSC®'s activities are now diverse and range from the involvement of indigenous peoples to occupational safety and species protection to a principle of democracy for all stakeholders.

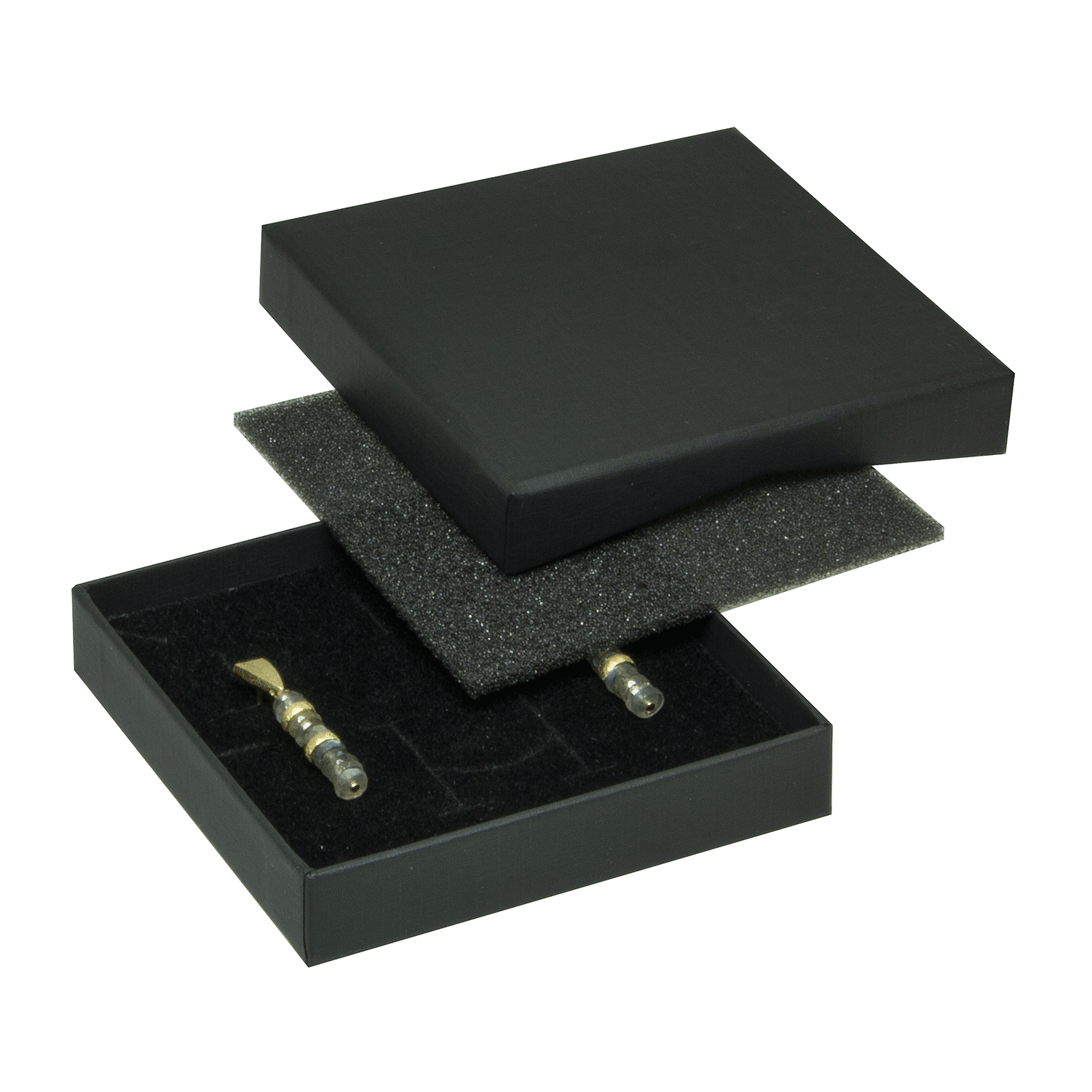

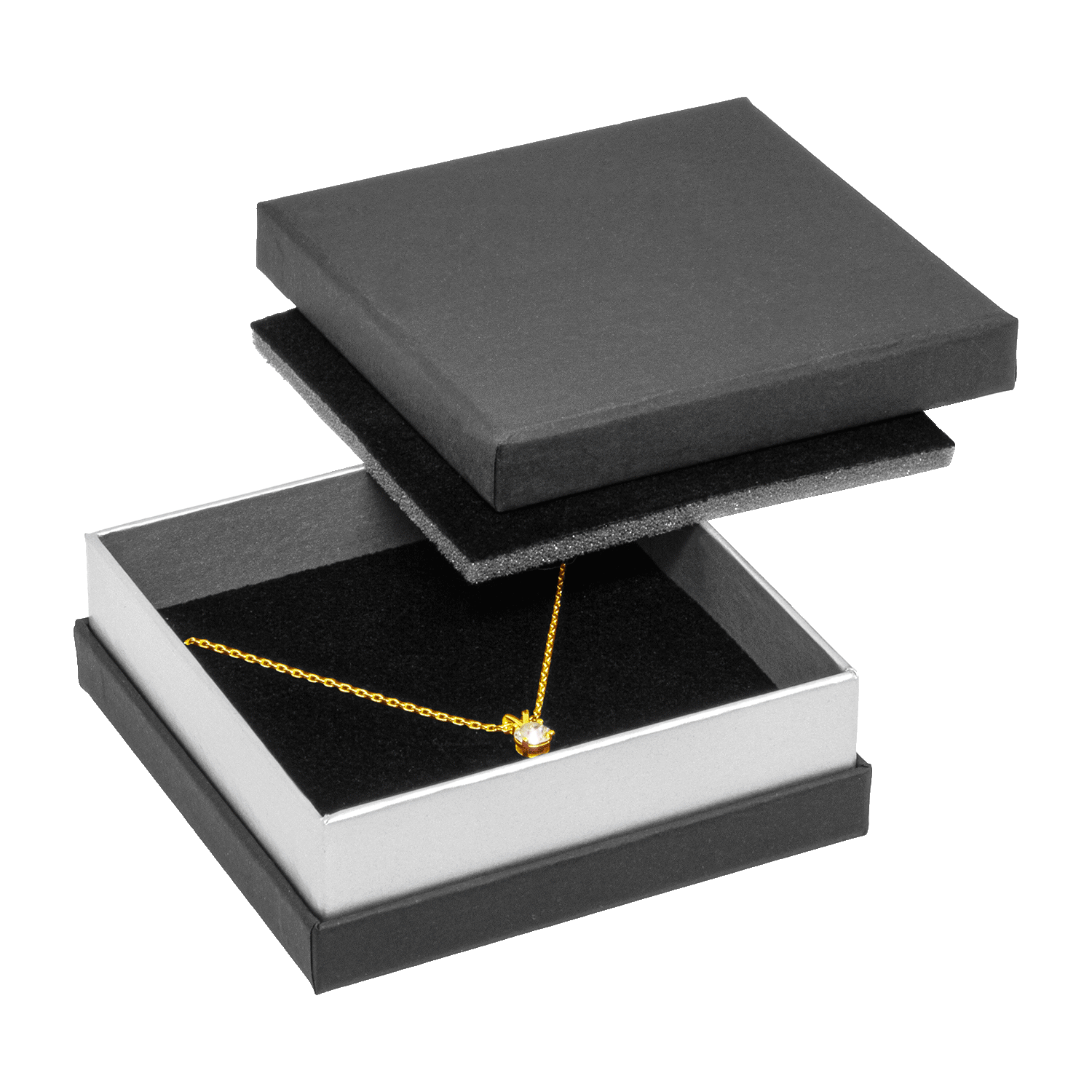

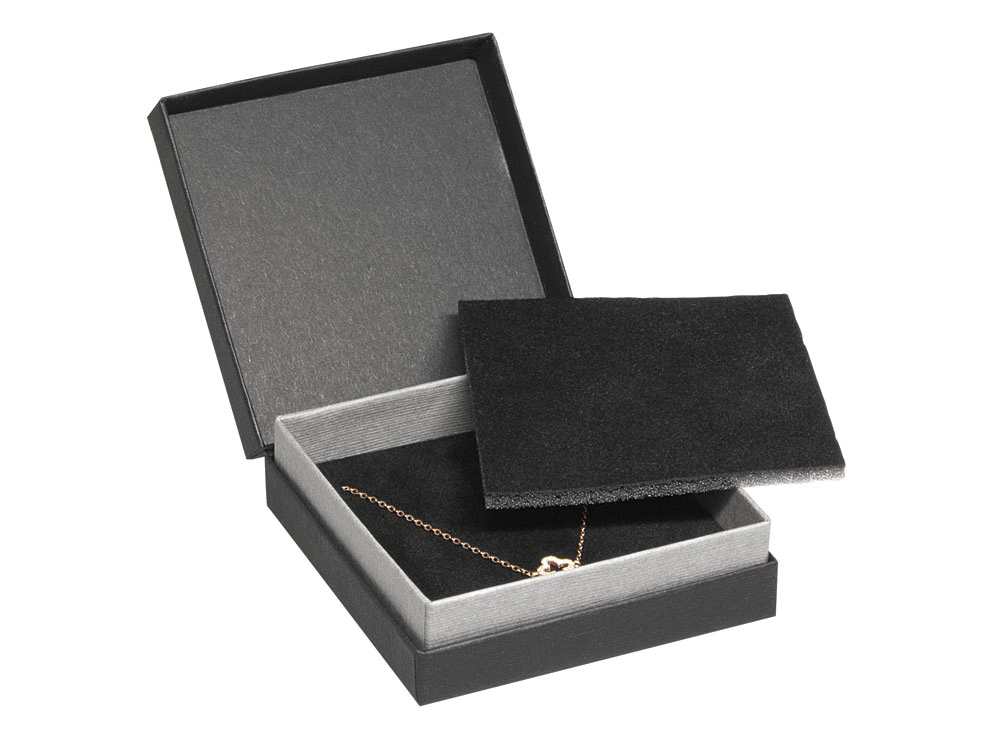

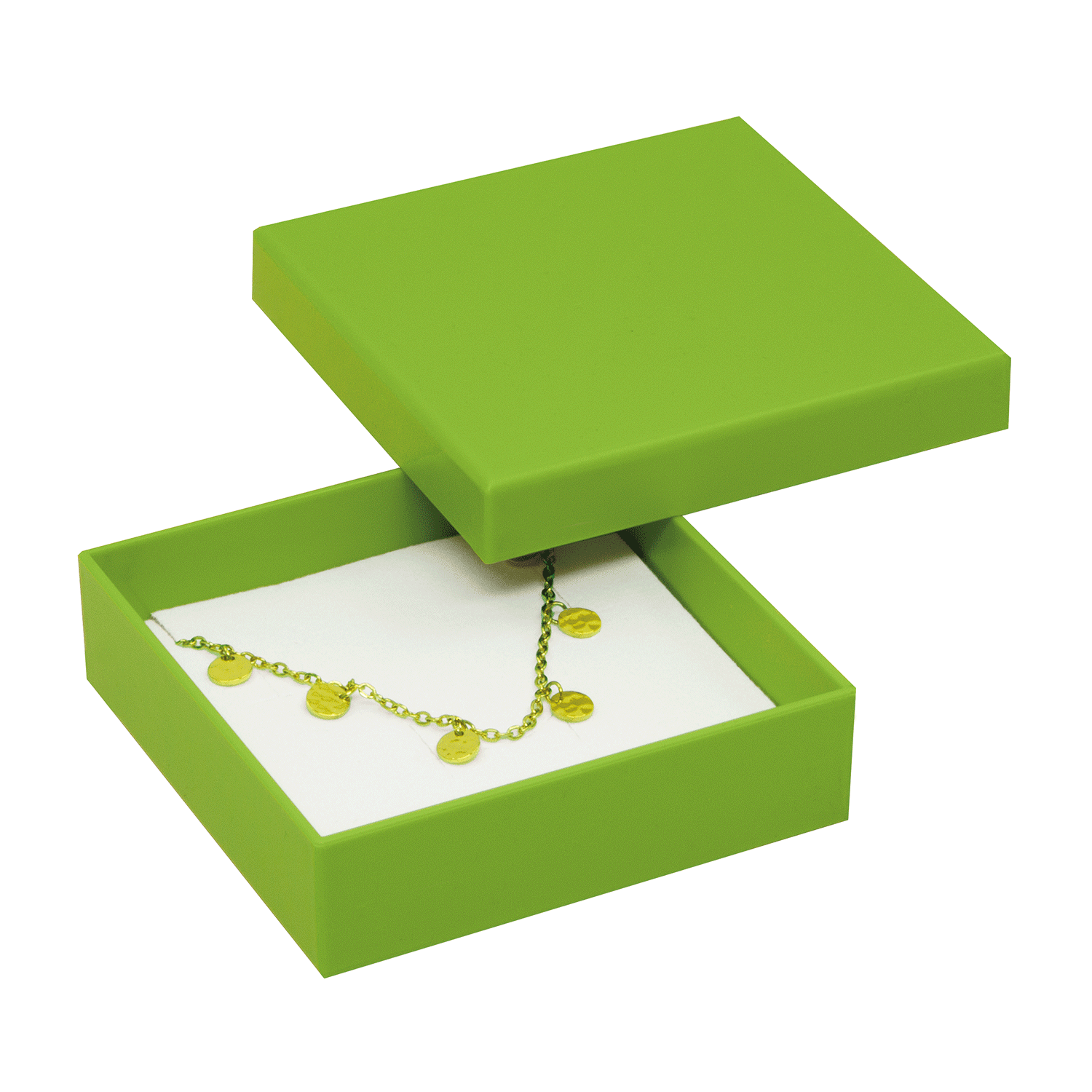

Our FSC®-certified packaging is made from materials sourced from responsibly managed, FSC®-certified forests and other controlled sources.

WHAT DOES THIS MEAN FOR LESER?

As our industry uses wood fibres on a large scale, we are committed to sustainable forest management with a complete chain of custody. As an internationally active company, we believe that treating the environment with care is also our responsibility. For us, this means proving that our product and supply chains are certified – from the forest to the consumer. This is because seamless control of the wood chain guarantees end products that meet the standards we set for ourselves. The FSC® label therefore gives consumers the certainty that they are purchasing positive end products from sustainable forestry. For LESER, this is another step towards responsible planning for the future.

Since then, our range has included several series and products with the FSC® label. All FSC®-certified packaging series can be found in our sustainable packaging overview, which we carry under the brand name GreenPack by LESER.

Discover sustainable packaging series now!

THE BACKGROUND – ENVIRONMENTAL IMPACT

Many industries are already feeling the effects of climate change. Climate-related complications in industrial supply chains and extreme heat waves and cold spells in the tourism industry are already a reality. These are signals from the environment, and we are taking decisive action to counter their causes with our environmental management system. This is because companies bear a significant share of the responsibility for the consequences of climate change. However, the motives behind certification are complex and range from environmental protection to responsible planning for the future. On the one hand, environmental management helps us to reduce our CO2 emissions, but it also enables us to save energy costs and thus operate sustainably.

INTERNATIONAL STANDARD FOR ENVIRONMENTAL MANAGEMENT

Many industries are already feeling the effects of climate change. Climate-related complications in industrial supply chains and extreme heat waves and cold spells in the tourism industry are already a reality. These are signals from the environment, and we are taking decisive action to counter their causes with our environmental management system. This is because companies are largely responsible for the consequences of climate change. However, the motives behind certification are complex and range from environmental protection to responsible planning for the future. On the one hand, environmental management helps us to reduce our CO2 emissions, but it also enables us to save energy costs and thus operate sustainably. [Source]

WHAT DOES THE ENVIRONMENTAL MANAGEMENT SYSTEM MEAN FOR LESER?

LESER has therefore committed itself to regularly evaluating the status and effectiveness of the management system. The quality and environmental officer therefore prepares an annual management report that presents the environmental and quality-related events of the past year. To implement the objectives and activities, all relevant activities are described in process, work and workplace instructions, and the corresponding responsibilities are defined. Our environmental guidelines include the use of advanced processes and the environmentally friendly design of products. We continuously reduce our environmental impact, for example through the careful selection of the materials we process. We consider communication with stakeholders to be essential in this regard. We set our own standards, which are higher than legal regulations or official requirements.

Further sustainability measures

Our company's low energy consumption is partly due to heat recovery from injection moulding machines, screw compressors and refrigeration machines. The integration of skylights to make use of daylight at workstations and the targeted use of night-time electricity also contribute to this. In short, around 20 energy recovery and energy saving processes are currently in use, some of which have been developed and optimised in-house.

The company mainly requires water for sanitary purposes and for cooling the injection moulding machines. Some of the water requirement is covered by rainwater, which is collected in a cistern and used for flushing toilets via a pump system. To minimise dust emissions for the benefit of our employees, appropriate extraction systems have been installed in the various production areas. In addition, carbon dioxide and nitrogen oxide emissions from the heating system are kept very low through the use of natural gas and efficient heat recovery. Precautions such as collection trays for water-polluting substances and an automatic fire alarm system with a wet water extinguishing system ensure that damage to the environment is kept to a minimum in the event of an incident.

The environmental management system enables us to continuously monitor our ongoing environmental impact. Internal audits, management documentation, training and further education for our employees ensure that internal standards are maintained and developed. This enables us to produce sustainable packaging – in every respect!